Boating in Osage Beach offers unforgettable days on the Lake of the Ozarks, but all that sunshine, water, and fun can take a toll on your boat’s finish. If you’ve invested in ceramic coating, you’ve already taken a major step in preserving your boat’s appearance and value. But here’s the thing: even the best ceramic coatings need proper maintenance to perform at their peak.

In this guide, we’ll break down the best practices for effective Marine Ceramic Coating Maintenance, specifically tailored to the environmental challenges of Osage Beach. Whether you’re new to boat care or a seasoned lake-goer, these tips will help you maximize the benefits of your ceramic coating for years to come.

Why Marine Coating Maintenance Is Essential in Osage Beach

The boating lifestyle in Osage Beach is undeniably rewarding, but also unforgiving on your boat’s surfaces. The Lake of the Ozarks environment presents a mix of factors that accelerate wear, even on ceramic-coated boats:

- Intense UV radiation leads to gelcoat fading, oxidation, and reduced gloss over time.

- Waterborne contaminants like algae, grime, and salt residue can cling to surfaces and break down protective layers.

- Dock rash and micro scratches occur frequently from tight marina spaces, boat-to-dock contact, and routine docking maneuvers.

- High humidity and mineral-heavy water contribute to water spotting, which, if left untreated, can etch into coatings and dull the finish.

- Pollen, sand, and organic debris settle on boats and often go unnoticed until they’ve already begun to degrade the surface.

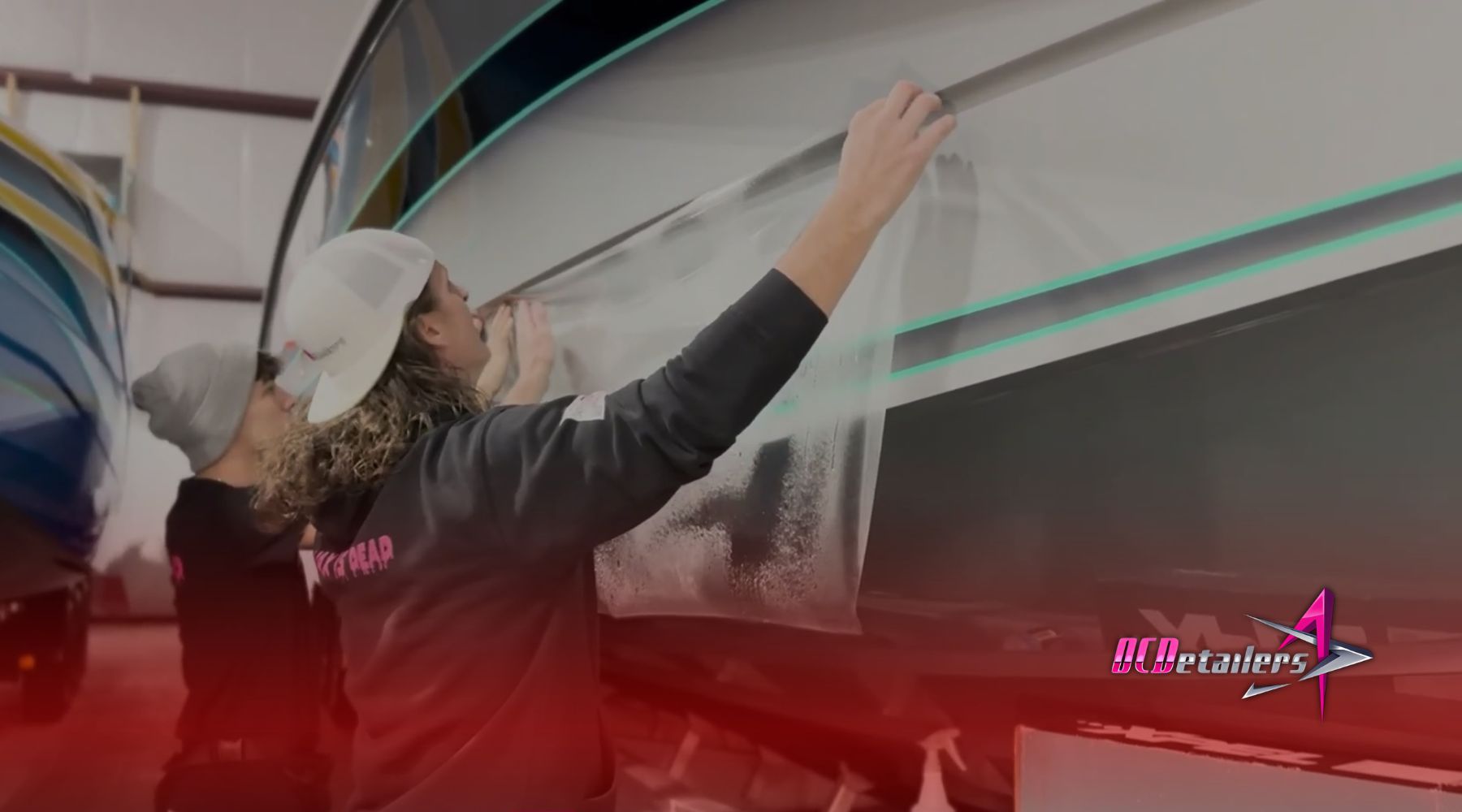

Even premium ceramic coatings need routine care to maintain their hydrophobic properties, oxidation resistance, and surface gloss. At OCDetailers, we tailor our services to Osage Beach’s unique climate, ensuring your investment stays protected all season long.

Boat Detailing in Osage Beach: Regular Cleaning as Your First Line of Defense

How Often Should You Wash a Ceramic-Coated Boat?

To maintain your boat’s gloss, surface integrity, and hydrophobic performance, it’s crucial to wash it every 1–2 weeks, or immediately after lake use, especially after exposure to heavy pollen, algae, or mineral-rich water.

Best Practices:

- Use a pH-neutral marine soap: Avoid dish soaps or automotive cleaners, which can strip ceramic layers. Choose ceramic-safe formulas designed specifically for marine use.

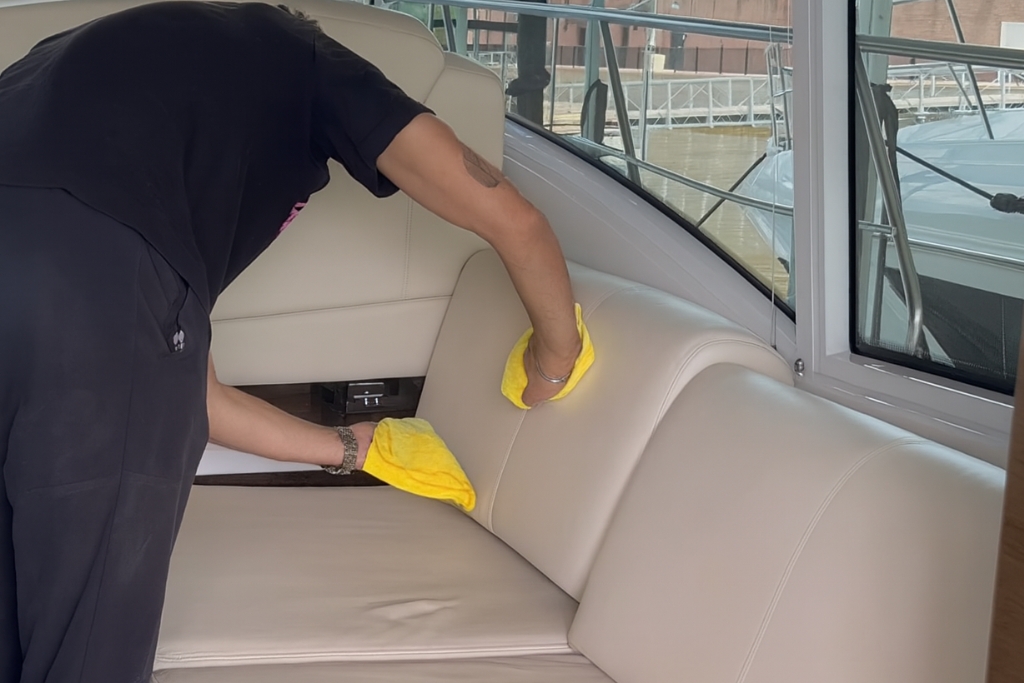

- Tools matter: Always use a soft microfiber wash mitt and dedicated towels to reduce swirl marks and micro scratches. Consider using separate mitts for the hull and topside to avoid cross-contamination.

- Rinse thoroughly with freshwater: This removes lake contaminants, prevents mineral buildup, and helps protect against premature coating failure.

- Dry immediately: Don’t let water evaporate under the sun. Use clean, high-quality microfiber towels to hand-dry all surfaces, including tight crevices, to prevent spotting and waterline etching.

Routine washing not only keeps your boat looking sharp, but it also extends the lifespan of the coating.

Immediate Contaminant Removal

Bird droppings, tree sap, bug splatter, and fish residue aren’t just cosmetic issues; they’re highly acidic and can permanently etch into your boat’s ceramic coating if not addressed quickly. These contaminants can also compromise the hydrophobic properties of the coating, making future cleanings more difficult.

Quick Response Is Key:

- Always carry a marine-safe spot cleaner, a spray bottle of freshwater, and a few clean microfiber towels for quick touch-ups while docked or after a day on the lake.

- Gently dab, don’t rub, to avoid scratching or spreading contaminants.

Pro tip: For stubborn marine algae cleanup or salt mineral deposits, use ceramic-safe descalers or decontamination sprays formulated specifically for coated boats. Regular removal helps maintain surface gloss and coating integrity without dulling or hazing.

Fast, gentle cleaning extends the life of your ceramic layer and keeps your boat looking pristine between washes.

Use Boosters to Maintain Protection

Over time, exposure to UV rays, minerals, and environmental pollutants can reduce the hydrophobicity and gloss of your ceramic coating. That’s where ceramic coating boosters, also known as SiO₂ sprays, play a crucial role in extending your protection between full reapplications.

Application Tips:

- Apply every 3–4 months, or after extended periods on the water, especially during peak boating season.

- Always apply in the shade and on a cool, clean surface to ensure even bonding and prevent streaking.

- Spray lightly and buff with a clean microfiber towel to restore deep gloss and slickness.

These boosters reinvigorate the coating’s protective layer, restoring water-beading performance, enhancing UV defense, and making future cleaning easier. For best results, pair your booster application with a professional wash or inspection, services available at OCDetailers.

Annual Inspections & Professional Reapplications

Even the most durable ceramic coatings have a lifespan, typically 1 to 5 years, depending on product quality, environmental exposure, and maintenance habits. Regular maintenance slows down wear, but annual inspections are essential to catch early signs of degradation before they affect your boat’s appearance or protection.

Signs It’s Time for a Touch-Up:

- Diminished water beading or sheeting action

- Surface dullness or haze that doesn’t improve after washing

- Increased drag, staining, or difficulty cleaning certain areas

- UV fading or chalkiness on exposed sections

At OCDetailers, our expert technicians assess coating condition, recommend coating boosters, and perform partial or full reapplications as needed to restore full protection and finish quality. Annual care ensures your boat stays showroom-ready and lake-proof.

How Marine Ceramic Coating Reduces Long-Term Maintenance

Unlike traditional waxes or sealants that wear off quickly, marine ceramic coatings chemically bond to your boat’s surface, creating a semi-permanent shield that significantly reduces upkeep.

Key Long-Term Benefits:

- UV protection that deflects harmful rays, preventing gelcoat fading and color degradation.

- Oxidation resistance shields the hull from environmental wear and chemical breakdown.

- A hydrophobic surface that repels water, dirt, and grime, making washes faster and less frequent.

- Stain prevention from fuel splashes, bird droppings, algae buildup, and mineral deposits.

By reducing the need for constant cleaning and waxing, ceramic coatings enable you to spend more time on the water and less time scrubbing or correcting damage.

Explore more advantages in our detailed Marine Ceramic Coating Benefits blog.

Final Thoughts

Proper Marine Ceramic Coating Maintenance isn’t just about aesthetics; it’s about protecting your investment, extending your boat’s life, and spending more time enjoying Lake of the Ozarks.

From expert application to maintenance support, OCDetailers in Osage Beach offers everything you need to keep your boat looking its best, season after season.

Need help maintaining your ceramic-coated boat? Contact us for expert detailing and protection packages.

FAQ: People Also Ask

How do you maintain marine ceramic coating?

Use pH-neutral cleaners, rinse after each use, dry with microfiber towels, and apply booster sprays every few months.

What is the best way to maintain ceramic coating?

Stick to a consistent wash routine, avoid abrasive tools, and keep your boat stored under cover when not in use.

How long does ceramic coating last on a boat?

With proper care, marine ceramic coatings can last 2–5 years, depending on usage and exposure.

Why is freshwater rinsing essential?

Lake water contains minerals and organic matter that can dull the coating or cause buildup. Freshwater prevents long-term damage.

Why do coatings lose hydrophobicity?

Exposure to UV rays, contaminants, and improper cleaning can degrade the surface. Regular maintenance and booster sprays restore performance.